Patented electronic controls system

Electronic Control Gear (ECG)

The patented Electronic Control Gear (ECG) is fitted with the most advanced controls to look after the performance of the Titanium AOP system.

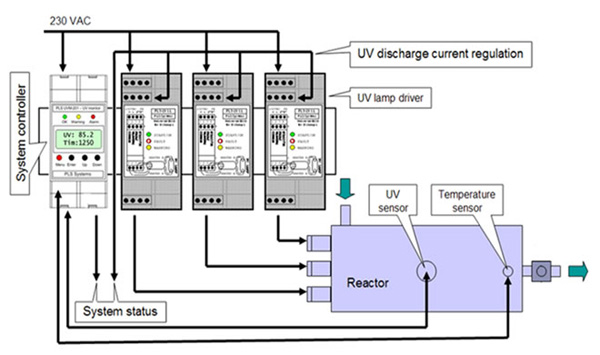

The traditional control system for UV units normally involves the use of a single controller that monitors the whole system’s performance. In contrast the Titanium AOP system is fitted with an independent controller for each operational part. There is one controller for each individual lamp within the system and another separate controller for the UV Monitor. This ensures a faster and simpler diagnosis of the system should it go into alarm. There is also an added benefit in that each aspect of the AOP’s performance can be individually checked and monitored to ensure they are operating at maximum efficiency.

Each control module is individually mounted in a bespoke busbar cabinet on a DIN-35 rail assembly. There will be one control module for each lamp and a final module that is the system monitor. This checks both the UV intensity and the water temperature. Should the intensity of the UV drop the system will go into alarm and if the temperature increases beyond pre – determined parameters the drain solenoid valve fitted to the reactor body will be operated. This will allow fresh cooler water to be introduced into the reactor vessel and is a further safeguard to ensure no over-heating of the system.

The operational status of the system can be checked remotely with a fault contact output from the UV monitor and system controller as shown.